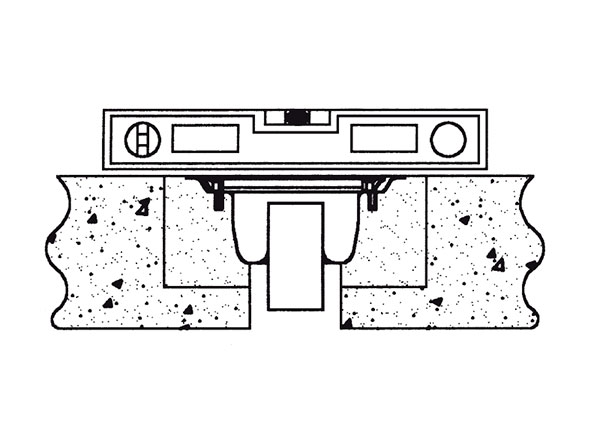

Dispositivo di Sicurezza

- I diversi modelli di rosette intercambiabili sulle basi unificate, permettono una maggiore adattabilità ai futuri cambiamenti dei locali, modifiche degli impianti e dei macchinari, facilitando così la riconversione degli immobili e la flessibilità nell’uso dei locali.

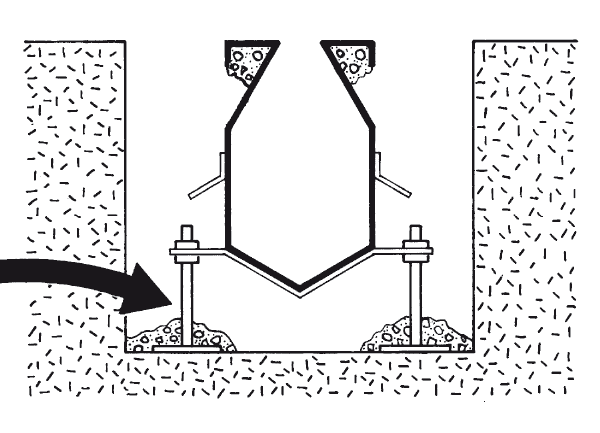

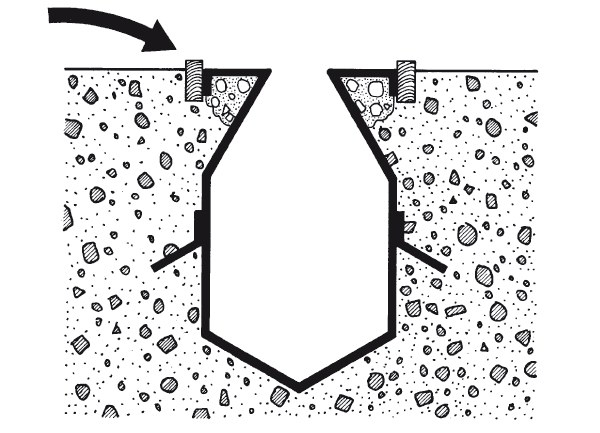

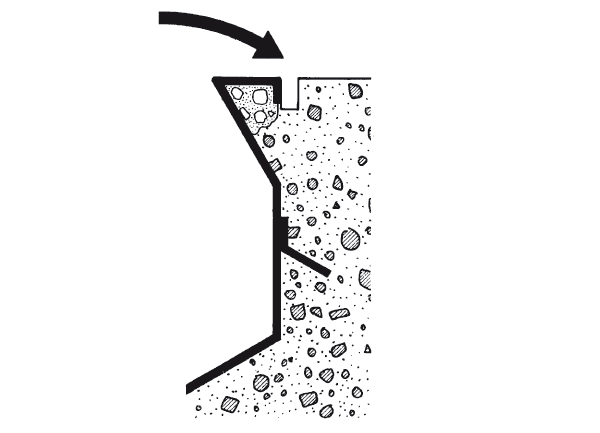

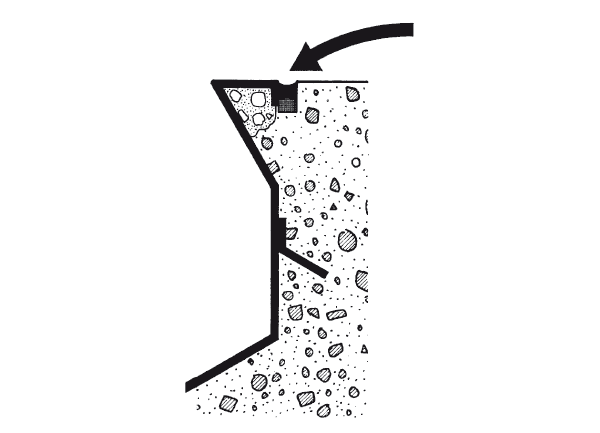

- Il numero dei chiusini e delle canaline deve essere sufficiente per recuperare le acque di scolo. La collocazione deve essere giudiziosamente scelta, in base alla concezione dei locali e degli impianti.

- Per limitare al massimo il percorso dello scorrimento e la stagnazione dello sporco, che è generalmente il maggior veicolo di contaminazione, la disposizione deve essere studiata per una evacuazione facile e rapida della massa di lavaggio, assicurando così anche un utilizzo più economico.